|

|

22-01-2012, 07:44 PM

22-01-2012, 07:44 PM

|

#1

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Decided to build my own diesels (pic heavy)

Donnors are Mercedes 320 CDI 6 inline

Ingredients :

Engine :

Turbos :

Stand alone ECU :

Wiring :

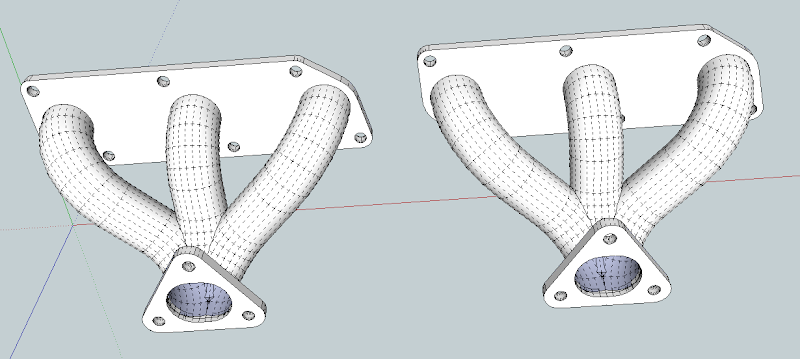

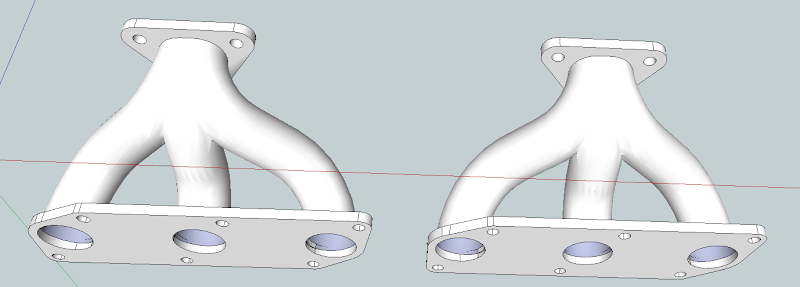

Custom manifolds :

|

|

|

22-01-2012, 07:44 PM

22-01-2012, 07:44 PM

|

#2

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

__________________

|

|

|

22-01-2012, 07:45 PM

22-01-2012, 07:45 PM

|

#3

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

If interested I'll keep updating the post.

Powergoal = 400 HP (half the weight of a Chevy BB)

Max 6000 RPM

Turbo's are watercooled VGT from garrett & can make 230HP a piece.

I have found a genius who is doing the programming.

The ECU is develloped here in Belgium.

I am putting 2 of them in one off my boats (raffshore F1) with Bravo 1 XZ & imco lowers

|

|

|

22-01-2012, 08:57 PM

22-01-2012, 08:57 PM

|

#4

|

|

Registered User

Country: Job Centre

Location: In a box

Occupation: Chaos's gofer

Interests: Skiving

Boat make: Spectre 30

Engines: 2 x Promax 225

Cruising area: In the bath

Join Date: Mar 2004

Location: In a box

Posts: 5,201

|

That all looks pretty impressive. Have you still got the workshop/showroom on the canal? I visited once with a couple of friends and Nico, probably around 6 years ago..

__________________

Chaos for Moderator.

|

|

|

22-01-2012, 10:02 PM

22-01-2012, 10:02 PM

|

#5

|

|

Registered User

Join Date: Sep 2008

Posts: 75

|

this is definitely one project worth following, not so much more guys building there own diesels anymore... Looking forward for more updates as you get along  Have fun

Cheers,

Rob.

|

|

|

23-01-2012, 01:37 AM

23-01-2012, 01:37 AM

|

#6

|

|

Registered User

Join Date: May 2009

Posts: 496

|

Recon those engines are realy strong had an old E320CDI with that motor, have heard of them being good for half a million miles plus. Have a freind that does a lot of Mercedes and only problem with those engines is injecter copper gasket leaks quite often.

Sure you have seen this link of Black smoke racings Mercedes with the same engine as you, but allways puts a smile on my face. The car has a Scania truck turbo and they are now putting out around 500bhp reliably

Realy interested to see how this project turns out, I think that will make and excellent marine engine with a bit of developemnt. Did think about using that engine instead of the later V6 but because of the extra length I would have lost the rear seats, also the later one is lighter with the aluminium block. However with a twin setup the engine will be quite narrow so you will be able to keep them quite close.

Keep up the good work and keep us posted.

|

|

|

23-01-2012, 07:56 AM

23-01-2012, 07:56 AM

|

#7

|

|

Registered User

Location: West Coast of Norway

Occupation: naval architect

Interests: surface piercing props, stepped hulls, air entrapment hulls

Boat name: none

Boat make: PetterTintorera

Engines: Yamaha 90

Cruising area: West Coast of Norway

Join Date: Sep 2005

Location: West Coast of Norway

Posts: 888

|

Very impresive! Whats the estimated build cost?

|

|

|

23-01-2012, 08:21 AM

23-01-2012, 08:21 AM

|

#8

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by Scand

Very impresive! Whats the estimated build cost?

|

That is a very good question

Good used Engine 3000 - 5000

Computer 3000

Turbo's 1200 (good used)

Sensors (EGT, EMP, MAP, Rail pressure, ...) 800

Intercoolers ?

Custom work ?

Injector upgrade 600

Bigger High Pressure Diesel pump : 450 (used)

Programming

Dyno time

So I would think around 15000 max ... ?

|

|

|

23-01-2012, 03:09 PM

23-01-2012, 03:09 PM

|

#9

|

|

Registered User

Country: uk

Location: liverpool

Interests: sailing ribing

Boat name: llyn raider

Boat make: 7m xs rib

Engines: 200 merc opti

Cruising area: n wales

Join Date: Nov 2006

Location: liverpool

Posts: 215

|

very cool stuff  will it run on red deisel or the god stuff from petrol stations?

__________________

I have a short attention span,  So i need at least two projects/basket cases at all times

|

|

|

23-01-2012, 05:53 PM

23-01-2012, 05:53 PM

|

#10

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by andyxs

very cool stuff  will it run on red deisel or the god stuff from petrol stations? |

What a nice question to ask.

|

|

|

23-01-2012, 10:46 PM

23-01-2012, 10:46 PM

|

#11

|

|

Registered User

Join Date: May 2009

Posts: 496

|

Quote:

Originally Posted by Raffshore

That is a very good question

Good used Engine 3000 - 5000

Computer 3000

Turbo's 1200 (good used)

Sensors (EGT, EMP, MAP, Rail pressure, ...) 800

Intercoolers ?

Custom work ?

Injector upgrade 600

Bigger High Pressure Diesel pump : 450 (used)

Programming

Dyno time

So I would think around 15000 max ... ? |

Great thing about this is if you blow an engine you just go and buy another from a breakers say £1000 to £1500, all the other expencive bits just bolt on.

Did think with this, if it was a legal race setup and was racing don't bother with sealed sytem just run raw water to save weight and fit 2 new engine each season £3000, would be cheap racing for 2 x 400bhp engines.

|

|

|

23-01-2012, 11:04 PM

23-01-2012, 11:04 PM

|

#12

|

|

numbskull

Country: United Kingdom

Location: South

Occupation: none

Interests: none

Boat name: Leviathan

Boat make: Phantom 28

Cruising area: South Coast

Join Date: Mar 2004

Location: South

Posts: 15,959

|

Quote:

Originally Posted by freddy21

Did think with this, if it was a legal race setup and was racing don't bother with sealed sytem just run raw water to save weight and fit 2 new engine each season £3000, would be cheap racing for 2 x 400bhp engines.

|

Making 400hp from that engine would almost certainly mean running a sealed system, if only to be able to run it pressurised to stop steam pockets forming in the hot areas.

Steam pockets = ultra rapid self destruct.

Diesels like a nice even warm block too, raw water cooling isn't too good at achieving that.

__________________

.

"I Agree with everything you say really!" - John Cooke to Jon Fuller - 26-01-2013

|

|

|

24-01-2012, 12:23 AM

24-01-2012, 12:23 AM

|

#13

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by Jon Fuller

Making 400hp from that engine would almost certainly mean running a sealed system, if only to be able to run it pressurised to stop steam pockets forming in the hot areas.

Steam pockets = ultra rapid self destruct.

Diesels like a nice even warm block too, raw water cooling isn't too good at achieving that.

|

Inteligent opinion, explain

How can steam pockets be created in a fresh water system

|

|

|

24-01-2012, 07:27 AM

24-01-2012, 07:27 AM

|

#14

|

|

numbskull

Country: United Kingdom

Location: South

Occupation: none

Interests: none

Boat name: Leviathan

Boat make: Phantom 28

Cruising area: South Coast

Join Date: Mar 2004

Location: South

Posts: 15,959

|

Quote:

Originally Posted by Raffshore

Inteligent opinion, explain

How can steam pockets be created in a fresh water system

|

The nature of the beast in a raw water cooled engine is that without a sealed system, with radiator cap/pressure relief valve (in the case of my V8 diesels, @ 15psi) the system is 'open' to the water exit so cannot hold a pressure. Without the system 'at pressure', the coolant can boil at any place within the cooling system where the material (block etc) exceeds 100 degrees C. Once a small pocket boils, the gas & vapour produced forms an insulation barrier and stops the colder surrounding coolant getting near the area and the chain reaction to super heated steam pocket is VERY rapid. Held to a pressure, this min boiling point is increased substantially. That is why the thermostat in a raw water cooled engine (typically a GM V8) is in the 60 degree C region, to ensure the engine is over cooled and not allowing any part of it to reach the critical 100C, whereas most closed systems use a thermostat close to 100C (in the 90+ region) My engines run 88 degree thermostats and 15psi coolant caps.

A pressurised system also stops foaming and bubbles as they aren't so easily formed with plenty of psi squashing the coolant.

__________________

.

"I Agree with everything you say really!" - John Cooke to Jon Fuller - 26-01-2013

|

|

|

24-01-2012, 05:09 PM

24-01-2012, 05:09 PM

|

#15

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by Jon Fuller

The nature of the beast in a raw water cooled engine is that without a sealed system, with radiator cap/pressure relief valve (in the case of my V8 diesels, @ 15psi) the system is 'open' to the water exit so cannot hold a pressure. Without the system 'at pressure', the coolant can boil at any place within the cooling system where the material (block etc) exceeds 100 degrees C. Once a small pocket boils, the gas & vapour produced forms an insulation barrier and stops the colder surrounding coolant getting near the area and the chain reaction to super heated steam pocket is VERY rapid. Held to a pressure, this min boiling point is increased substantially. That is why the thermostat in a raw water cooled engine (typically a GM V8) is in the 60 degree C region, to ensure the engine is over cooled and not allowing any part of it to reach the critical 100C, whereas most closed systems use a thermostat close to 100C (in the 90+ region) My engines run 88 degree thermostats and 15psi coolant caps.

A pressurised system also stops foaming and bubbles as they aren't so easily formed with plenty of psi squashing the coolant.

|

Yes, all true.

There alot of pro & contra for raw water or sealed systems.

If I was going to run the engine at standard rated HP & RPM I would have gone the sealed way with a heat exchanger.

Now, in a engine were heat will be my biggest enemy, I decided to try raw water (and its easier  )

Thing is that with the raw water pump & speed off the boat you always create water pressure in the engine and I am not affraid of pockets that boil because off the amount of water running through the engine.

The thermostat I will leave at first to see how it reacts and then go from there

|

|

|

24-01-2012, 05:26 PM

24-01-2012, 05:26 PM

|

#16

|

|

Registered User

Country: England

Location: Great Horwood

Join Date: Mar 2005

Location: Great Horwood

Posts: 2,372

|

Off Thread

Mum, Julie, Martin, James, Charlotte & I send our best!

Miss those warm evenings in Spain with you eating the most, drinking the most & still swimming 10 laps of the pool after!

|

|

|

24-01-2012, 07:30 PM

24-01-2012, 07:30 PM

|

#17

|

|

numbskull

Country: United Kingdom

Location: South

Occupation: none

Interests: none

Boat name: Leviathan

Boat make: Phantom 28

Cruising area: South Coast

Join Date: Mar 2004

Location: South

Posts: 15,959

|

Quote:

Originally Posted by Raffshore

Yes, all true.

The thermostat I will leave at first to see how it reacts and then go from there

|

Be careful, If I was determined to run raw water cooling on a diesel (which I wouldn't), I would have a restriction at the water exit to maintain some sort of pressure within the block. Remember V6 mercs such as XR2 had restrictor washers in place of thermostats for that very reason, removing them to 'let it free flow' caused problems.

All JMHO

Good luck.

__________________

.

"I Agree with everything you say really!" - John Cooke to Jon Fuller - 26-01-2013

|

|

|

24-01-2012, 10:48 PM

24-01-2012, 10:48 PM

|

#18

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by Jon Fuller

Be careful, If I was determined to run raw water cooling on a diesel (which I wouldn't), I would have a restriction at the water exit to maintain some sort of pressure within the block. Remember V6 mercs such as XR2 had restrictor washers in place of thermostats for that very reason, removing them to 'let it free flow' caused problems.

All JMHO

Good luck.

|

All 2,5 engines running more then 8000 (longtime) big restrictors, under the small hole.

Advantage that we have with our computer is that we monitor all parameters all the time, water pressure will be one off them

|

|

|

24-01-2012, 10:53 PM

24-01-2012, 10:53 PM

|

#19

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

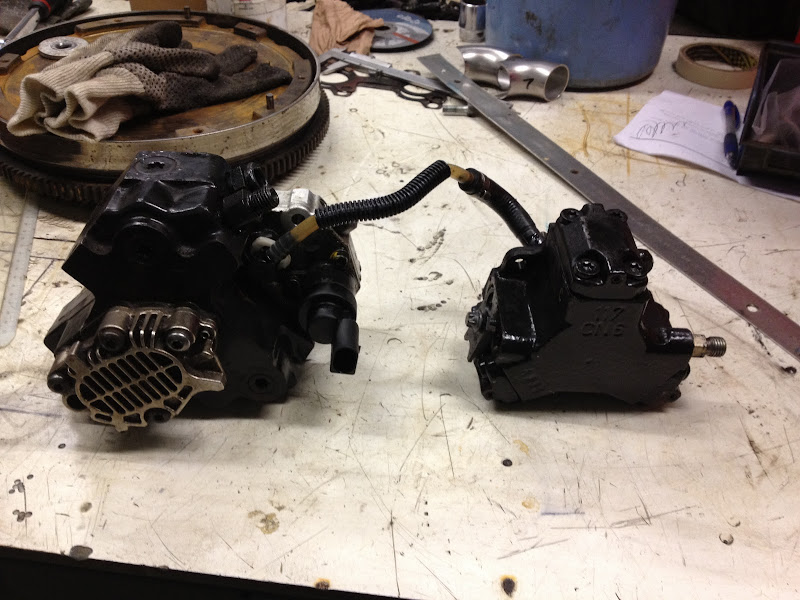

new vs old high pressure pump

|

|

|

24-01-2012, 11:38 PM

24-01-2012, 11:38 PM

|

#20

|

|

Registered User

Country: Belgium

Join Date: Sep 2005

Posts: 96

|

Quote:

Originally Posted by Ciao

Mum, Julie, Martin, James, Charlotte & I send our best!

Miss those warm evenings in Spain with you eating the most, drinking the most & still swimming 10 laps of the pool after!

|

I was training since I added the 2011 Barcelona Ironman to the list

Nice to hear from you, give me a ring sometime!

Love to the familly !!

__________________

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|